Disinfecting High-Touch Areas in Printer

To disinfect high-touch areas on your printer, focus on control panels, buttons, touchscreens, paper trays, and output bins. Power off and unplug the device first. Use a lint-free microfiber cloth with an EPA-approved, non-abrasive disinfectant—preferably hydrogen peroxide-based or alcohol-free—to avoid damage. Wipe surfaces lightly and let them air dry fully before use. Clean daily for hygiene and deeper weekly disinfection for thoroughness. Following precise steps guarantees effectiveness and longevity—more detailed guidance can help you optimize this routine.

Identifying High-Touch Areas on Your Printer

Where should you focus your cleaning efforts when disinfecting a printer? Begin with a systematic touchpoint analysis of the printer components. Identify areas frequently contacted during operation—control panels, buttons, touchscreens, paper trays, and output bins. These are your primary high-touch zones. Avoid less-contacted internal parts unless maintenance dictates otherwise. Document each component’s interaction frequency to prioritize cleaning tasks effectively. By concentrating on these critical touchpoints, you reduce contamination risks and maintain operational freedom without unnecessary over-cleaning. This targeted approach guarantees efficiency while safeguarding the printer’s functionality. Regularly revisiting your touchpoint analysis allows adjustments based on usage patterns, maximizing hygiene without compromising accessibility or performance. Your focus should remain on these key components for precise, effective disinfection.

Recommended Cleaning Materials and Disinfectants

Selecting the appropriate cleaning materials and disinfectants is essential for effectively sanitizing your printer’s high-touch areas without causing damage. Use lint-free microfiber cloths to avoid scratches and fiber residue. For disinfectants, prioritize eco friendly options such as hydrogen peroxide-based or alcohol-free solutions to minimize environmental impact while maintaining disinfectant effectiveness. Guarantee the chosen disinfectant has EPA-approved claims against bacteria and viruses relevant to your needs. Avoid bleach or abrasive chemicals that can degrade plastic surfaces and electronic components. Apply disinfectants sparingly using a dampened cloth rather than spraying directly to prevent moisture ingress. By choosing materials and disinfectants with proven efficacy and compatibility, you maintain both cleanliness and printer longevity, giving you the freedom to operate safely and sustainably.

Step-by-Step Guide to Safe Disinfection

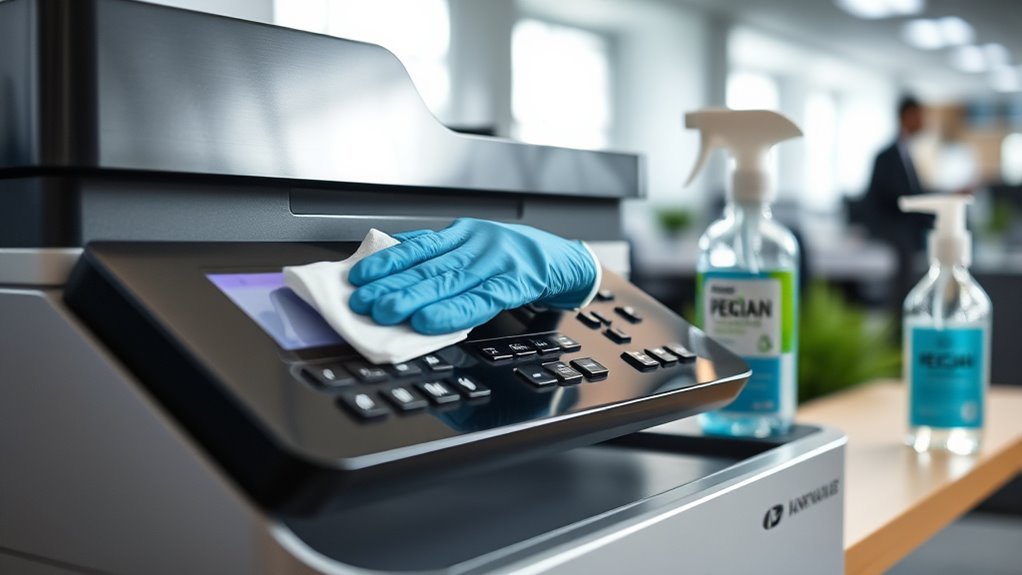

After choosing the right cleaning materials and disinfectants, you’ll want to follow a systematic approach to disinfect your printer’s high-touch areas safely. First, power off and unplug the printer to avoid electrical hazards. Use a lint-free cloth dampened with an approved disinfectant to wipe buttons, touchscreens, handles, and paper trays. Avoid soaking surfaces; apply disinfectants sparingly to prevent damage. Allow the surface to air dry completely before powering the device back on. Follow manufacturer guidelines for compatibility with cleaning agents to guarantee longevity. These printer maintenance tips safeguard functionality while maximizing sanitization effectiveness. Remember to wear disposable gloves during the process and dispose of them properly afterward. By adhering to these sanitization techniques, you maintain a hygienic workspace without compromising your printer’s performance or your freedom to operate it confidently.

Frequency of Cleaning for Optimal Hygiene

You should clean high-touch areas on the printer daily to maintain basic hygiene and reduce contamination risks. Schedule a weekly deep disinfection to target less accessible components and guarantee thorough sanitization. Additionally, perform event-driven sanitization immediately after any suspected contamination or heavy use.

Daily Cleaning Necessity

Although printers might seem like low-risk surfaces, their high-touch areas require daily cleaning to maintain peak hygiene. You should integrate this into your printer maintenance tips by establishing a strict daily cleaning schedule. Focus on buttons, touchscreens, paper trays, and handles, using appropriate disinfectants compatible with printer materials to avoid damage. Follow a consistent procedure: power off the device, apply disinfectant to a lint-free cloth, and gently wipe each high-contact surface. This routine minimizes contamination risk and keeps your workspace healthier without sacrificing freedom or productivity. Adhering to daily cleaning schedules guarantees peak hygiene, reduces the spread of germs, and extends your printer’s lifespan. Remember, precision in your daily cleaning routine is key to effective printer maintenance.

Weekly Deep Disinfection

While daily cleaning addresses surface-level contaminants, weekly deep disinfection targets stubborn germs and buildup in hard-to-reach areas of your printer. Incorporate a consistent cleaning schedule that includes a detailed inspection of internal components like rollers, trays, and control panels. Use approved disinfection techniques such as applying isopropyl alcohol with lint-free cloths or specialized disinfectant wipes to guarantee efficacy without damaging sensitive parts. Carefully disconnect power before cleaning to avoid electrical hazards. Focus on crevices and joints where debris and microorganisms accumulate over time. Allow sufficient drying time to prevent moisture damage. By adhering to this structured weekly protocol, you maintain peak hygiene, extend your printer’s lifespan, and enjoy uninterrupted freedom in your workflow without the risk of contamination buildup.

Event-Driven Sanitization

Since printer usage varies depending on specific events and user interactions, event-driven sanitization tailors cleaning frequency to actual contamination risk. You’ll need to identify event triggers such as high user volume or visibly soiled surfaces to activate sanitization protocols. This approach guarantees peak hygiene without unnecessary cleaning, preserving your freedom to focus on productivity.

| Event Trigger | Recommended Action |

|---|---|

| End of high-traffic day | Disinfect all high-touch areas |

| Visible dirt or smudges | Immediate spot cleaning |

| Shared device usage | Sanitize after each user group |

| Paper jam resolved | Clean touchpoints involved |

| Scheduled intervals | Routine check and sanitize |

Follow these precise protocols to maintain cleanliness aligned with actual risks.

Precautions to Avoid Damage During Cleaning

Before you begin disinfecting high-touch areas on your printer, make certain to power it off and unplug it to prevent electrical damage or injury. Use recommended cleaning techniques: apply disinfectants to a lint-free cloth instead of spraying directly to avoid moisture intrusion. Wear protective gear such as nitrile gloves to shield your skin and prevent chemical exposure. Avoid abrasive materials that can scratch sensitive surfaces or remove printer labels. Use minimal liquid and guarantee it doesn’t seep into openings or vents, which could cause malfunction. Follow manufacturer guidelines for approved disinfectants and cleaning intervals. By adhering to these precautions, you maintain your printer’s functionality while effectively sanitizing high-touch points, ensuring both device longevity and your operational freedom.

Benefits of Regular Printer Disinfection

Taking the right precautions during cleaning not only protects your printer but also maximizes the effectiveness of regular disinfection. By routinely disinfecting high-touch printer areas, you reduce microbial buildup, which directly supports your health benefits by minimizing exposure to harmful pathogens. This practice also guarantees consistent printer performance, delivering a notable productivity boost by preventing malfunctions caused by dirt and grime.

| Benefit | Impact |

|---|---|

| Health Benefits | Reduces pathogen presence, promoting well-being |

| Productivity Boost | Guarantees smooth operation, minimizing downtime |

| Device Longevity | Prevents wear from contaminants, extending lifespan |

Regular disinfection grants you freedom from health risks and operational interruptions, empowering you to maintain an efficient, safe workspace.

Frequently Asked Questions

Can Disinfecting My Printer Void Its Warranty?

You shouldn’t worry too much—disinfecting your printer usually won’t void warranty policies if done correctly. To maintain your warranty, follow manufacturer guidelines carefully during printer maintenance. Avoid using harsh chemicals or soaking components, and guarantee the device is powered off and unplugged before cleaning. By sticking to recommended procedures, you retain warranty protections and keep your device safe, allowing you the freedom to maintain hygiene without risking coverage.

Are There Eco-Friendly Disinfectants Safe for Printers?

Like choosing a gentle breeze over a storm, eco-friendly options for disinfecting your printer prioritize printer safety without harsh chemicals. Opt for isopropyl alcohol diluted to 70% or hydrogen peroxide solutions, which clean effectively yet protect sensitive components. Always apply disinfectants to a soft cloth first—never directly on surfaces—to prevent damage. This approach guarantees thorough sanitation while maintaining your device’s integrity and your freedom to use it worry-free.

How Do I Disinfect Internal Printer Components Safely?

To disinfect internal printer components safely, start by powering off and unplugging the device. Use safe materials like isopropyl alcohol (70%) applied sparingly with a lint-free cloth or cotton swabs for internal cleaning. Avoid harsh chemicals or excessive moisture that could damage electronics. Gently wipe accessible parts without disassembling sensitive components. Let everything dry completely before reassembling and powering on. This approach guarantees effective sanitation while preserving your printer’s functionality and your freedom to maintain it.

Can UV Light Be Used to Disinfect Printers?

When it comes to UV effectiveness, don’t put all your eggs in one basket. UV light can disinfect surfaces but may not reach all printer crevices or internal parts, limiting its thoroughness. For printer safety, avoid prolonged exposure to UV as it can degrade plastic components and sensitive materials. Use it as a supplementary method, combine with standard cleaning, and always follow manufacturer guidelines to maintain your printer’s longevity and your freedom from damage.

Does Disinfecting Affect Print Quality or Ink Longevity?

When disinfecting your printer, you won’t typically see a direct impact on print quality or ink longevity if you avoid applying liquids near sensitive components. Use a soft cloth with approved disinfectants on external surfaces only. Excess moisture or harsh chemicals can degrade ink cartridges or internal parts, potentially reducing ink longevity and causing print quality issues. So, proceed carefully to maintain your printer’s performance and freedom from unnecessary wear.